Risk Assessment

Rave Limited has the expert knowledge for identifying threat conditions, component failure modes and to evaluate failure

consequences

allowing us to produce practical and useful risk assessment solutions for energy assets

Risk Assessment

Rave Limited have experience in applying risk assessment principles and methodologies. We can assist operators to develop risk assessment models to add ress their unique pipeline integrity issues

Most pipeline operators manage risks through compliance with regulatory requirements and/or application of guidance in industry Standards. Other operators perform activities to mitigate risks where a failure occurs, or where it is recognized either through or experience that an asset could be at risk of been significantly impacted or fail. Sometimes these approaches may not occur in a structured manner, and the level of risks or required mitigation may not be well determined. The objective of a risk assessment is to implement a structured process to identify credible threats to pipeline or facility assets, evaluate the likelihood that the identified threats could potentially cause failure to the assets, and assess the consequence of failures in the event it fails.

A risk assessment process generally comprises of the following key steps:

- External corrosion;

- Internal corrosion;

- Stress corrosion cracking (SCC);

- Pipe manufacturing features;

- Construction/fabrication-related defects;

- Equipment-related threats;

- Mechanical damage;

- Incorrect operation,

- Weather-related and outside force (WROF) events.

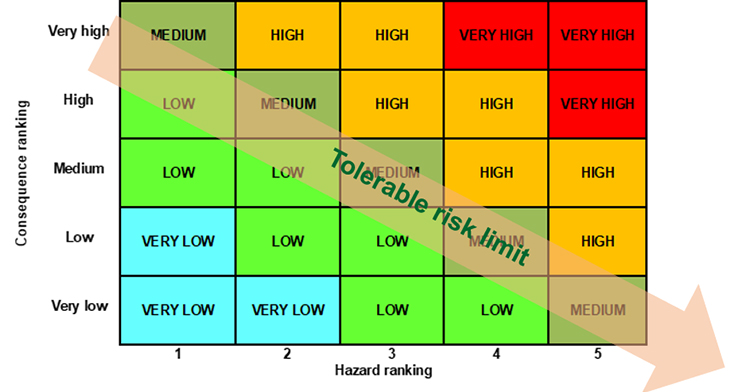

The probability that a specified undesirable event will occur depends on a host of factors that can be time dependent or time independent. Risk management comprises an estimation of the risk, deciding whether or not it is tolerable and exercising appropriate control measures to reduce the risk to tolerable levels. But the key is how to decide what risk is and is not tolerable.

Services we Offer

- Optimize inspection strategies (Risk based inspection or RBI);

- Inform Replace Versus Repair decisions;

- Cost benefit analysis as part of due diligence for asset acquisition purposes;

- Select appropriate mitigate or repair methods to keep risk at acceptable levels;

- Feasibility of extending the life of an asset;

- Feasibility of extending the life of an asset;

- Prioritize pipeline segments for integrity assessments and/or repair

Risk Assessment Methodologies

The following are risk evaluation methodologies that can be implemented by experts at Rave Limited:

- Quantitative Risk Assessment (QRA)

- Qualitative Risk Assessment

- Hazard Identification (HAZID)

- Failure Modes, Effects, and Criticality Analysis (FMECA)

- Fault Tree Analysis (FTA)

Quantitative Risk Assessment

Several industry standards provide guidance on the application of pipeline QRA either to existing pipeline assets or to proposed developments in the vicinity of high pressure pipelines.

The Risk Assessment Working Group (RAWG) of the United Kingdom Onshore Pipeline Operators Association (UKOPA) has published QRA guidance in two documents: IGEM/TD/2 for natural gas pipelines; and PD 8010-3 for other major accident hazard pipelines containing flammable substances such as liquid petroleum gas (LPG). The Canadian Standard CSA Z6622015 Annex B also provide guidance on performing QRA. ASME B31.8S also provide commentary on risk assessment approaches that could be implemented by an operator.

Risk Acceptance Levels & The “ALARP”

Principle

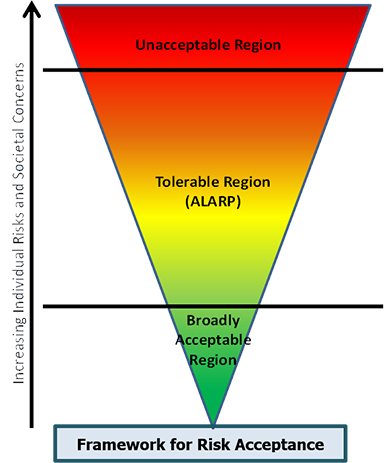

As Low as Reasonably Practicable or “ALARP” is a principle used in risk assessment and refers to the concept that efforts to reduce risk should be continued until the incremental sacrifice (in terms of time, effort, cost, or other expenditure of resources) is grossly disproportionate to the value of the incremental risk reduction achieved.

If there is a gross disproportion between the reduction in risk and the effort required, then no action is required to reduce the risk. The goal of risk assessment is ensure that risk levels are ALARP.