RELIABILITY ANALYSES

Holisticly brand sustainable solutions rather than clicks-and-mortar applications.

Phosfluorescently whiteboard fully tested initiatives.

RELIABILITY ANALYSES

Reliability analyses services we offer:

- Structural Reliability Analyses (SRA),including:

o Probability of Failure (POF) Analysis;

o Probability of Exceedance (POE) Analysis. - RAM ― Reliability, Maintainability and Availability Analyses.

Structural Reliability Analysis (SRA)

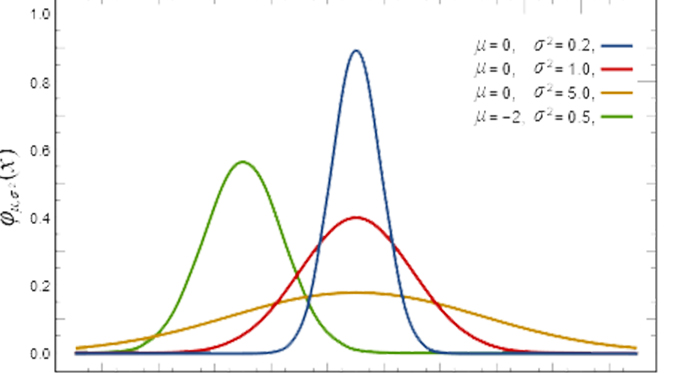

The fitness-for-service analysis methods discussed previously are deterministic approaches: these approaches using single point values to represent randomized attributes of a pipeline. Deterministic assessments have typically have several layers of conservatism that normally represent the worst-case scenarios, which oftentimes do not represent actual risk levels for the entire pipeline system. Structural reliability analysis better accounts for variation in assessment variables and uncertainties in the assessment parameters in more detail than a deterministic assessment, producing results that are more realistic.

SRA is a method for calculating the reliability of a pipeline using a probabilistic analysis approach. Reliability is defined as the probability that a pipeline will not fail during a given period of time, which is commonly considered as the intervening time before the next scheduled reassessment.

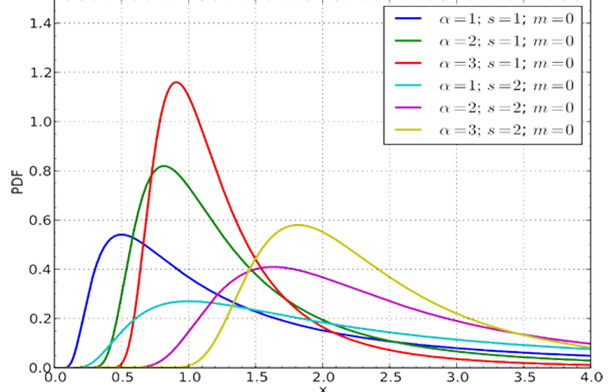

SRA is generally more rigorous than deterministic type analyses and require detailed data on pipe property and flaw distributions such as distribution of yield and tensile strength, flaw sizes, material toughness, wall thickness and diameter variations, and others.

SRA ― Probability of Exceedance (POE)

Rave Limited can perform a Probability of Exceedance (POE) analysis for corrosion features to determine the probability that a flaw of any indicated size could exceed a size of concern or require repair during a given period of time.

SRA ― Probability of Failure Analysis (POF)

Rave Limited can also use reliability-based assessment approaches to evaluate the probability of failure (POF) for identified linear indications, giving the result as a POF rather than as “pass” or “fail,” or a fixed time to failure.

Reliability, Availability & Maintainability (RAM)

A RAM analyses is typically used to improve production efficiency and to optimize performance of pipeline systems or process plants.

The SRA approaches discussed previously is an example of Reliability methods. Maintainability (M) is the probability that a failed system will be restored or repaired to a specified condition within a given period of time. Availability (A) is a function of Reliability and Maintainability and describes the probability that a repairable system will perform its intended function at a given point in time or over a specified period of time when operated and maintained in a specified manner. RAM is a techniques used to evaluate system integrity of critical integrated components in a facility.