INSPECTION PLANNING

Holisticly brand sustainable solutions rather than clicks-and-mortar applications.

Phosfluorescently whiteboard fully tested initiatives.

INSPECTION PLANNING

Inspections must provide information about a pipeline threat that leads to greater understanding of the probability of failure due to the threat. There are two main ways in which this is achieved: by inspection to monitor the degradation of the pipeline condition or by inspecting to periodically confirm that the pipeline has not suffered a random event that has increased the failure probability.

Services we offer

- Inspection planning;

- Selection of appropriate inspection technology and tools;

- Remaining Life and Reassessment Interval Assessment

- Piggability studies;

- Inline inspection qualification;

- Inspection data review and analysis.

Inspection Planning

Performing inspection for effective monitoring of pipeline condition and identification of pipeline damage requires proper planning of inspection strategies. This requires knowledge and experience of the type of likely threats that could affect a pipeline or asset based on its design, construction, material, operation, environment, external forces, manufacturing processes, defect or failure history, amongst other important information.

Selection of Appropriate Inspection

Technology & Tools

Experts at Rave Limited have extensive experience advising operators on the selection of appropriate inline (ILI) technologies including conventional magnetic flux leakage (MFL) circumferential MFL (CMFL) Spiral MFL (SMFL), ultrasonic crack detection ((UTCD), UT Wall Measurement (UTWM), Eddy current (EMAT) and geometry inspection technologies. We have also supported operators in selecting appropriate nondestructive examinations techniques including the use of Magnetic Particle Inspections for surface defects, Phased Array UT, among many other inspection techniques.

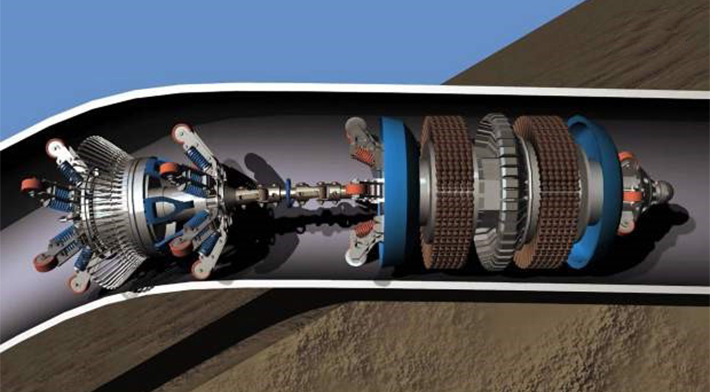

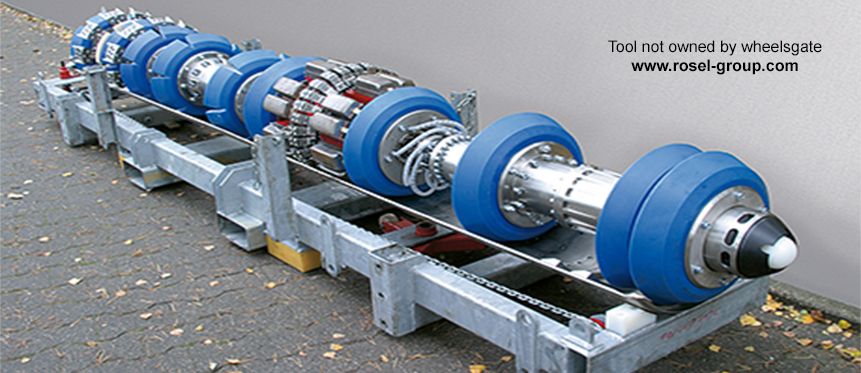

Piggability Studies

A thorough examination of the mechanical and operational characteristics of the pipeline to be inspected must be conducted in order to determine the feasibility of ILI and to select the optimum tool.

Rave Limited has the ability and experience to support operators in identifying key project activities necessary to execute a successful ILI pig run, namely:

- Investigate the feasibility of pigging (piggability) of the pipeline;

- Review the options for preparatory pigging and Inline Inspection (ILI);

- Remaining Life and Reassessment Interval Assessment

- Identify any potential pigging operational issues and recommend corrective actions;

- Assessment of wax or debris build up in pipeline which could prevent a successful pigging run.

Inspection Qualification

Rave Limited can develop processes for validating ILI tool performance from field inspection data within the guidelines in API 1163 standard. This process would involve matching indications from field investigations to corresponding features observed in the ILI to evaluate the inspection tool performance, as well as reviewing overall system and process results.

Data Review/Analysis

Accurate interpretation of inspection data and characterization of pipeline defects or threats is essential for integrity management. Rave Limited has the capability for performing reviews of ILI data and NDE reports to establish the type, nature and size of indications identified by inspection