OUR PROJECTS

Facilities and topsides engineering, SURF (Subsea, Umbilicals, Risers & Flowlines) engineering, pipeline design,

construction management, installation, and many more...

OUR PROJECTS

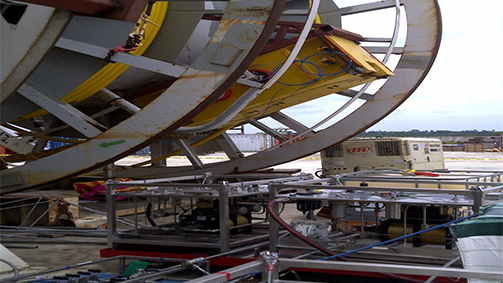

Sub-Sea Control UMBILICALS and UMBILICAL systems are Electro/Hydraulic control umbilical's that connect Top-side Equipment (FPSO) to Sub-Sea equipment. They are made up of Hydraulic control lines for valves and manifolds, Chemical injections (Methanol), Electric cables for power and signal communications and lastly Fiber Optic cables for Top to Sub-sea communications.

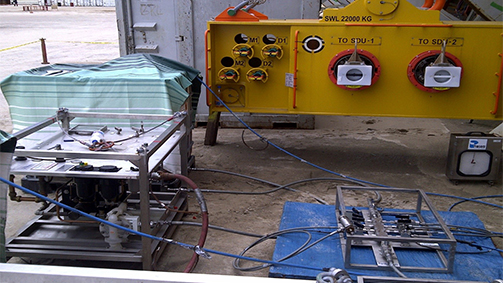

Rave Limited Engineering Services has the competence and equipment to carry out all UMBILICAL Tests to Industry Guidelines Specifications 13628-5. Petroleum & Natural Gas Industries - Design and Operations of Sub-sea Production Systems - Part 5; Sub-sea Umbilical's, Identical to API 17 E Specification for Subsea Umbilicals.

Our Test Scopes Covers:

- Load Out Monitoring

- Post Load-Out Testing

- Transportation Monitoring

- Installation Monitoring

- Post Lay Testing

- Post Hook-Up Testing

- Commissioning and Function Testing

Fluid cleanliness analysis (NAS 1368 Class 6/SAE AS 4059 6B-F), pressure monitoring, Electric Continuity Resistance Test (CR), Insulations Resistance (IR) and Time Domain Reflectometer (TDR).

Projects Our Current Key Personnel were involved in:

USAN FPSO (TOTAL/SAIPEM) Umbilical Yard Test: Loading, Post-Load out, Transportation and Installation Monitoring AGBAMI FPSO (Chevron/Technip) Umbilical Yard Test, Loading, Post Loading, Transportation, Installation and EFL tests.

Hydraulic Umbilical Testing

In 2019, our Rave Limited engineers implemented, supported and managed the pumping and testing operations involved in the precommisioning of several subsea control systems umbilicals for AMNI International Petroleum Development Company Limited, on behalf of our client, the West African Ventures. Our testing and pumping operations were completed using our Air Driven Liquid (hydraulic) pump.

Rave Limited high pressure pumps have been used to pump fluid at pressures of 100psi – 10,000psi depending on client’s requirement and needs. These pumps are used mainly in oil, water and chemical pumping. They are also used for injecting chemicals.

Our air operated, high flow, double headed-double acting hydraulic pumps are well proven and trouble-free operation.

In 2019, our engineers supported and managed a routine pigging operations project on the 24-inch Eriemu to UPS trunk pipeline in Nigeria from the design/Engineering stage through execution and completion. The project was completed on behalf of Heritage Energy Operational Services Limited for Shell Petroleum Development Company of Nigeria.

The project involved the cleaning of the 24’’ trunk line using series of pigs ranging from low density, medium density, high density, and a Bi-Directional cleaning pig. The pigs were propelled at a speed of 0.5m/s through the trunk-line. After each run, the pigs were inspected to confirm the cleanliness status of the pipeline.

Rave Limited staff was involved in the management and maintenance of a 24-inch valve on Eriemu to UPS Trunkline. The project was part of a routine pigging operations work park D (24-inch Eriemu to UIPS TL) on behalf of Heritage Energy Operational Services Limited for Shell Petroleum Development Company of Nigeria. This project was completed in 2019 in Nigeria.

As part of our commitment to the project goals of our clients, we supported initial planning of a recent pipeline construction project. As part of our support activities, Rave Limited engineers performed site visits to the client's facility to ascertain field conditions and to gather relevant project data related to resources, physical tie-in adapters, connections etc, among other data. This provided critical input during the planning stage of the project