FAILURE ANALYSES

Our work products are comprehensive, produces concise and clear conclusions

as we ll as practical actionable recommendations

FAILURE ANALYSES

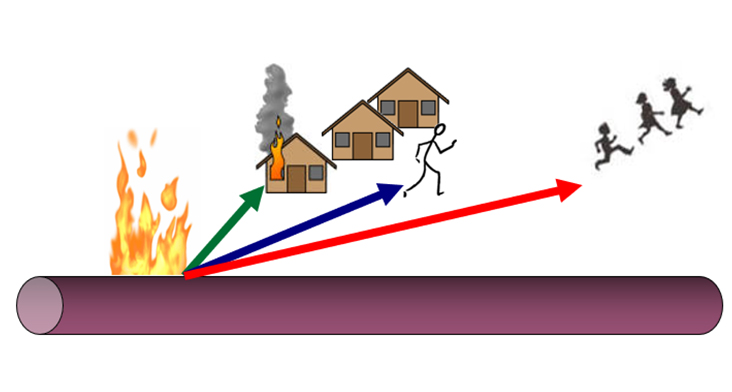

Hazardous liquid and gas pipelines are relatively safe compared to other forms of energy transportations. However, they do fail, and failure could cause fatalities, environmental damage and business losses. Pipeline could fail as a leak or a rupture. Causes of pipeline failures vary around the world, and from country to country. The leading causes have generally been due to corrosion and third-party damage. The gas standard ASME B31.8S identified Nine (9) categories of threats conditions that could potentially cause pipeline failure, namely:

- External corrosion;

- Internal corrosion;

- Stress corrosion cracking (SCC);

- Pipe manufacturing features;

- Construction/fabrication-related defects;

- Equipment-related threats;

- Mechanical damage;

- Incorrect operation,

- Weather-related and outside force (WROF) events.

These threats are also applicable to liquid pipelines, but liquid lines are typically more susceptible to fatigue failures compared to gas lines due to more aggressive pressure cycling. Failure could also be result from interaction between these threat conditions, causing failure in situations where a failure would normally not occur from the presence of individual threats. To mitigate or prevent the re-occurrence of future failures, it is important that operators conduct a comprehensive review and analysis to gain understanding of credible threats to their pipeline assets.

Services we Offer

- RCFA ― Root-Cause Failure Analysis.

- Failure Investigation Support

- Independent third-party reviews and verification of failure investigation reports and analysis

Root-Cause Failure Analysis (RCFA)

An RCFA is a structured approach used to identify the underlying cause(s) of a failure incident so that the most effective solutions can be identified, and correct actions implemented, to avoid a recurrence. The RCFA process/structure leads to examination of all factors that could have affected the performance of equipment or personnel that led to the occurrence of the incident. Rave Limited staff are experienced in using commonly used techniques for conducting an RCFA, including, but not limited to:

- Fault-Tree Analysis;

- Cause-and-Effect Tree;

- Timeline Analysis;

- Why Analysis;

- Fishbone Analysis;

- FMECA/FMEA

Failure Investigation Support

Expert at Rave Limited have experience supporting operators in developing failure investigation plans, and also in in the execution of such plans to investigate the cause of a failure, and to characterize the threat conditions responsible for it. Specific support activities may include:

- Site visit plans;

- Design of laboratory pipe/material test program;

- Performance of metallurgical examinations;

- Conduct document reviews of pipeline design, operation, repair history, failure history, inspection records (girth weld, radiography, ILI, testing), hydrostatic test records, and others;

- Development of engineering models to evaluate pipeline condition and significance of identified or suspected defects,

- Application of best practice evaluation principles in relevant industry standard and research documents;

- Conduct HAZID workshops;

- Pipeline route surveys to evaluate geohazard conditions;

- Amongst others, as necessary.

Independent Reviews of Third-Party

Failure Studies

Rave Limited can perform independent reviews of failure investigation studies conducted by other consultancy companies for operators who want a second opinion on completed studies. Oftentimes such additional work may be needed to verify or validate findings from failure analysis studies, or simply to critique an existing study. This would assist operators in making informed decisions, particularly when uncertainties exist regarding conclusions and recommendations from previous studies, or new data become available that may necessitate an update and or could impact findings from previous studies.